Blog

Hydraulic Hose Routing Mistakes That Cause Premature Failure (And How to Avoid Them)

July 21, 2025

Avoid costly downtime with Broda Hose. Learn the top hydraulic hose routing mistakes that cause premature failure and how to prevent them effectively.

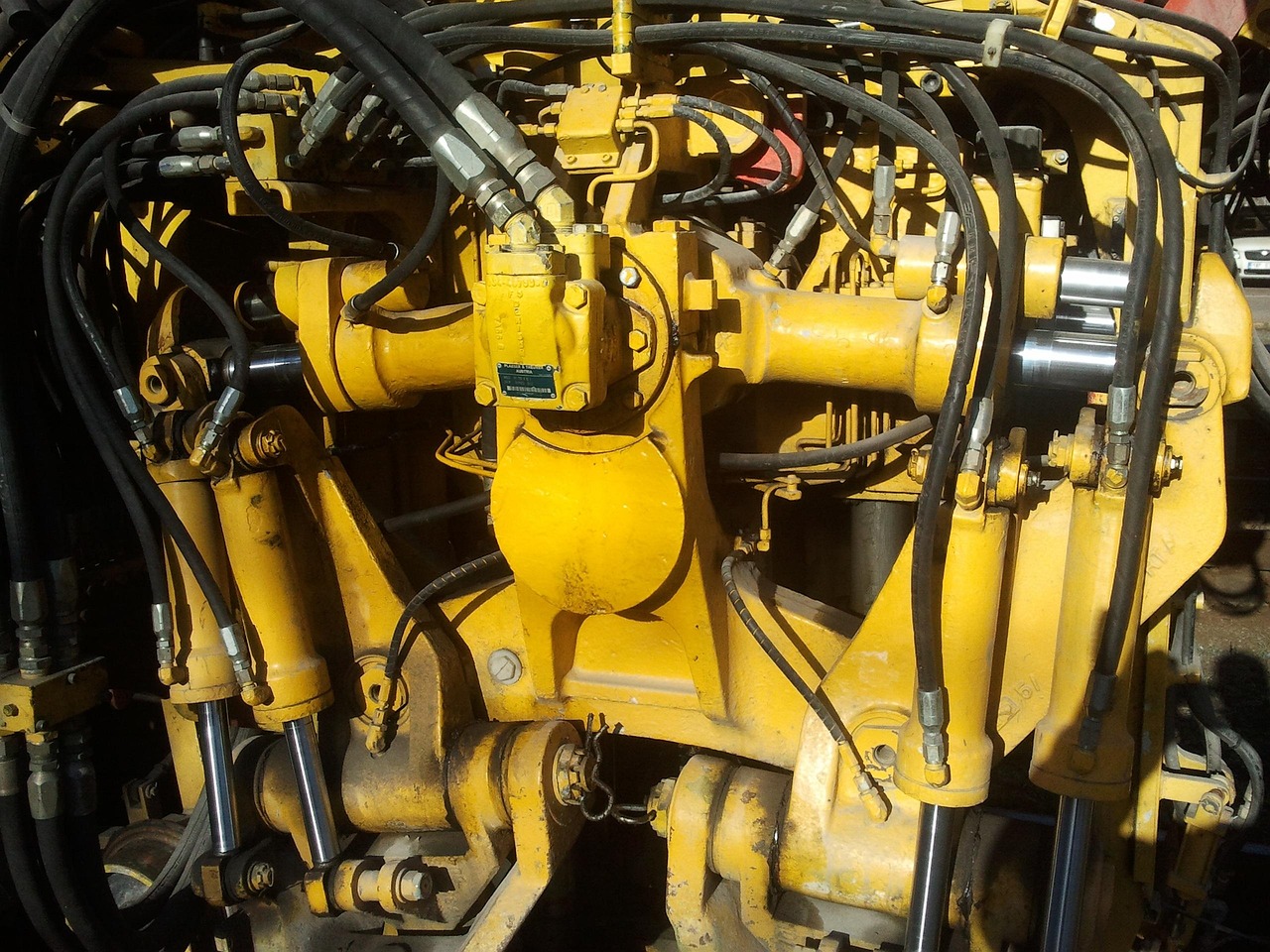

Many professionals prioritise hose quality but often overlook the importance of proper routing in hydraulic systems. Hydraulic hose routing mistakes can quickly lead to equipment failure, costly downtime, and safety hazards. With correct layout and installation, hoses perform more efficiently, last longer, and withstand demanding industrial conditions.

Why Correct Hose Routing Is Essential to Avoid Premature Failure

Even the most durable hose can fail early if routed incorrectly. Poor routing adds stress, restricts flow, and exposes hoses to heat or friction. Every installation should focus on proper positioning and support.

When planning or inspecting hose routing, consider the following:

• Bend Radius Compliance: Ensure the hose follows the manufacturer’s minimum bend radius to prevent internal damage.

• Avoid Contact and Abrasion: Keep hoses clear of sharp edges and abrasive surfaces.

• Allow for Movement: Provide adequate slack and support for moving components.

• Heat Management: Position hoses away from high-temperature areas.

• Proper Length: Avoid tension or sagging by measuring hose lengths accurately.

By addressing these details, operators can reduce unnecessary wear and extend the service life of their hydraulic assemblies. Below are the most frequent hydraulic hose routing mistakes and the best practices to avoid them.

Mistake 1: Ignoring Minimum Bend Radius – Exceeding the manufacturer’s specified bend radius weakens the hose reinforcement and leads to cracking or kinking. Always follow bend radius guidelines and use angled fittings when needed to maintain smooth flow paths.

Mistake 2: Excessive or Inadequate Slack – Too little slack creates tension and pulls on the fittings, while too much causes sagging and abrasion. Hoses should have controlled movement that matches the equipment’s operational range.

Mistake 3: Twisting and Multi-Plane Bending – Twisting the hose during installation alters the alignment of its internal reinforcement, causing premature fatigue. Ensure that the hose lies naturally in a single plane and check the layline for signs of twist before tightening fittings.

Mistake 4: Poor Support, Clamping & Contact Points – Incorrect or missing clamps allow hoses to vibrate or rub against nearby components. Secure hoses with proper clamps at straight sections, avoiding bends and high-stress points.

Mistake 5: Routing Near Heat Sources or Abrasive Surfaces – Exposure to heat, chemicals, or rough materials can degrade the outer cover and inner layers. Use protective sleeves, guards, or reroute the hose away from high-temperature or abrasive zones.

Mistake 6: Failing to Consider Movement & Dynamic Loads – Hoses attached to moving machinery must accommodate dynamic loads and vibration. Allow sufficient freedom for motion while ensuring that the hose does not stretch, twist, or rub under load.

Mistake 7: Over-Length or Under-Length Routing (Wrong Hose Length) – A hose that is too short puts strain on fittings and connections, while one that is too long creates unnecessary loops. Always measure accurately and maintain a balanced, direct path between connection points.

For expert guidance on safe hydraulic equipment practices, refer to the safety alert from SafeWork NSW.

Broda Hose: Your Partner in Preventing Hydraulic Hose Routing Mistakes

Avoiding hydraulic hose routing mistakes starts with professional design, precise measurement, and quality installation. At Broda Hose, we specialise in supplying and assembling hydraulic hose solutions that meet Australian industry standards and withstand demanding operating conditions. Our team ensures that every hose is correctly routed, properly supported, and tested for long-term performance.

For professional hydraulic hose assemblies, fittings, and routing advice, contact us, your trusted hydraulic partner in Australia.

Related Blog Articles:

Choosing the Right Hydraulic Hose: A Guide for Melbourne’s Industrial Sector

Address Hydraulic Hose Failures with On-Site Replacement by Broda Hose

Optimized by: Netwizard SEO